|

| Proposed future state VSM |

Over the last couple of posts, I’ve been working through an example of using a high-level value stream map (VSM) to uncover opportunities that deliver actual practical actions for change. The VSM showed how the imbalance between site and factory leads to increasing inventory and costs as several building sites are needed to match the factory output. This led to the proposal ‘balance site and factory lead times’ as a breakout objective for a Hoshin Kanri X matrix, along with a future state map and the strategies, initiatives, and measurements needed to deliver results.

This example showed not only how these powerful tools work,

but also how quickly and easily they can deliver results. Instead of spending months

working to populate a VSM with data, you can start focusing on changes that deliver

an impact, then using that change process to fill out the details. Focusing

your resources where they are needed, as opposed to risking a model line that

struggles to demonstrate the power of lean due to surrounding constraints.

In the last post one of the processes targeted for reduction

was ‘hand over’, driving it down from 2 weeks to less than 2 days, our Hoshin

plan highlighted strategies and initiative that will start to deliver this, such

as, right first time and eliminating of snagging rework. But another factor is

making sure all information is in the right hands at the right time ready for the

final hand-over. Failing to do this can lead to significant waste causing

delays to the project and preventing completion. Waiting on information is a

common issue throughout the whole value stream and is the biggest cause of delays

I’ve witnessed. Issues involve missing factory drawings, specific details or

dimensions, and material specifications causing direct delays to purchasing and

production. But the handover of information is also critical for approvals such

as warranty, fire sign off, and building control, without which, stops the

project hand over.

In the previous post I mentioned briefly that a full VSM is

more than just mapping the process flow, and the example is technically an

unfinished document. Mapped across the top of the diagram should be the flow of

information, what is needed, who needs it and why it’s needed. Understanding

this is absolutely critical and spending time to fill this out can massively reduce

risks later in a project. As with all Lean processes it’s best to start closest

to the customer and work backwards as you expand the VSM and once complete

you’ll have your ‘golden thread’.

The Golden thread is one of those buzz words I’ve raised as

an issue before, it’s often spoken about without any real specific detail on

how to do it or what it is or should be. Without understanding what you need

and why there is a risk of gathering information for information’s sake, which

is over processing and so waste, ultimately the information flow from the VSM

shows what’s needed for a complete golden thread.

|

| Information Flow added to the high level VSM |

Using the future state VSM from the last post we can sketch

out key information milestones and link them to their source. For this example,

we’ll focus on the handover requirements as part of our Hoshin plan and expand

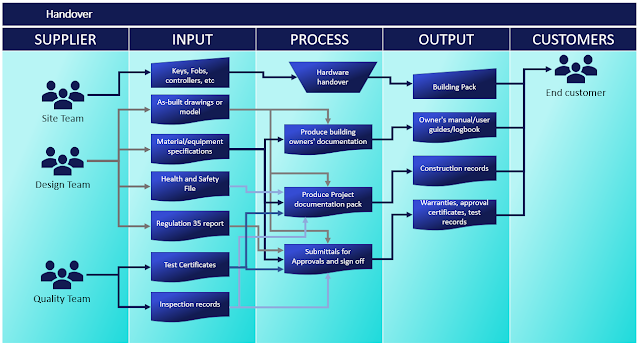

out some of the VSM stages. A good tool to support, with this is known as SIPOC

(suppliers, Inputs, Process, Outputs and Customers). By producing a SIPOC

diagram on the handover stage we can start to expand on the processes that need

to happen and list out what the process customers’ needs are. In turn that will

show what inputs are needed and then who the suppliers are.

|

| Example SIPOC of the handover process |

This diagram is far from comprehensive and the next step would be to work with all the interested parties to ensure it's accuracy and expand the processes into their own diagrams. But even at this generic level it has value linking the suppler of information to what it's used for, knowing that we can make sure we know how we're going to do that and ensure a smooth handover. The diagram also demonstrates that the information falls into two main supply categories;

- Design information

- Evidence of the build process

Traditional clerk of works and building control processes struggle with the offsite setting due to structure of the work progress. Instead of building batches, in phases, in one location where the inspector can visit and sign off a single phase of work across a project in one go. The volumetric offsite process should be a flow process with modules at all stages of work very quickly from manufacturing start to site install and finishing. In the example we’ve been looking at, it takes around a week from the project start to the first module ready for delivery. So, it’s vital to capture your evidence along the way as smoothly and efficiently as possible.

Logically then a digital system would seem to be the way to go and there is no shortage of available companies that have products that can help. The difficulty here is that it again gets into a world of abbreviations, acronyms and buzzwords. Terms like IR4.0, MES, QMS, IOT, RFID, RFI, NCR, BIM, ITPs and more. This can be a minefield of options where one software package does about 40% really well, has addons for another 30-40% and just doesn’t have anything for the remaining. On one project when we reviewed options for external systems it involved 5 different companies/software packages that needed to work together. While one company was going to be our main supplier and responsible for coordinating the rest this does bring a risk of delays for updates and support, or worse if there is a falling out between the suppliers. On the flip side I’ve working in factories that run on printed forms made in excel, manually completed and scanned. Having to update and format the Excel file for new projects was time consuming and frustrating, so I turned to macros to automate this process, saving a week or more of admin for each project. That still didn’t solve the biggest issues though as no matter how fancy or advanced a system is, if they aren’t used you won't have the data you need to deliver those hand over processes.“We shouldn’t be

marking our own homework”

Last year I wrote about culture, and this is a prime example

of a culture of ‘not our job’ causing problems, a production team that wants

quality to have sole responsibility for filling out inspections will then be

stood around waiting (and likely complaining) for the inspectors to carry out

the inspections.

This is where the Lean pillar of built-in quality is so important; no one should know the job better than the people who do it. The workers on the shop floor who do a job day in, and day out should know what good looks like better than anyone. When completing a quality sign off record and taking pictures, they’re presenting the work as completed. It’s not marking the homework it’s filling out the answer sheet saying you are done and have completed the task to the required standard. Likewise, the quality team are not there to mark your work but are an ally, proofreading your submission, a second pair of eyes to help avoid mistakes passing forward and ensuring the required information is captured clearly. Even a dedicated quality bay is there to back up the signoffs and function as a safeguard against issues going down the line, getting harder to spot and exponentially more expensive to put right.

So, who’s marking that homework? First up is the warranty

provider and building control; they are the ones who sign off the building as

safe and complete. Then should the worst happen incident investigators will go

over that paperwork and records with a fine comb with serious consequences if

it fails to pass muster.

Ensuring a strong cultural attitude towards quality is the first step towards successfully delivering a golden thread and being able to ensure that documentation is completed ‘right first time’, ‘on time in full’. This then opens the ability to submit that documentation through the project at milestones, reducing the amount that needs to be reviewed at the final handover helping to deliver the targets of the X matrix. To aid with this the system should not be a burden on the workforce and this is where modern digital platforms begin to shine because they can add advantages that outweigh the manual actions of filling out forms. But with so many options how do you choose?

Keep it simple remembering that the core aim of the system is to gather the evidence. Get that specification worked out first then decide what else to add with a reason for each feature you choose to add. It doesn’t have to be all singing all dancing on day one, and in the past, I developed a working system in Microsoft Access that offered several benefits over the printed forms

- eliminated the need for printing and scanning

- could run reports to pdf for checking work in progress and completion

- supported production control and kept track of module progress

- gave live updates and tracking to a big screen

- could be saved as an app so you don’t even need a 365 license for the whole shop floor

The extra features for live updates and production control benefited the production supervisors, production engineers and quality teams by removing a significant amount of admin work, freeing up their time to be out on the shop floor supporting the team.

|

| MS Access Proved surprisingly capable as a live digital system |

Not everything is perfect though and the downsides of this approach included,

- user lag, the system could be a little slow to run and needed optimisation

- multiple app instance feeding into a core database on the server common drive caused some development headaches

- it couldn’t be used to take photos though it can track and manage photos taken manually on the device

- it’s still very manual for the shop floor staff

- it’s limited by the features of access and visual basics which are pushed very hard already to tackle the 1st two points

- Limited or no integration outside of the database to wider business systems like planning or purchasing/financial

- Internal resource needs to maintain the system and there was a lot of bug chasing to start with

The next step up is an external specialist supplier and

there are a range of standard systems on the market that do a fantastic job

delivering the benefits listed and overcoming the majority of the downsides.

Considerations do need to be made towards the 40/40/20% and multi package

systems mentioned earlier but working with a supplier can get a system up and

running quite quickly. One problem in particular though is, building site

integration, most off the shelf factory systems are aimed at traditional manufacturing

environments they may not be suitable for the site team, and vice versa. Additionally, the systems can still be a

burden on the shop floor workers both from the time to fill out forms and working around large panels or modules requiring the return to a workstation or looking after a tablet. So,

it’s important to look at options and possibilities to capture the information

as smoothly as possible or better yet take advantage of technological advances so

that working with the system is easier than not.

- Delivery of drawings and build information. This can be through the tablets and screens which offers the ability to zoom in on details and have quick links between files, they can also use layers or step by step instructions to simplify drawing to only what’s needed for each step of a process. There are even projection systems that can display the information onto the workspace.

- Automatic quality measurements, such as dimensional checks or squareness, by having the system replace a task it makes the operatives life easier and advances in photogrammetry and AI are making this more affordable for more tasks.

Finding the right system that already has these integrated and able to interface with traditional construction design systems can be difficult. The size of offsite components is likely to need a bespoke solution and in the case of AI and photogrammetry will need a supplier who’s willing to work with you to develop these new technologies and adopt them live into their software quickly.

It was a combination of

- the risk factors,

- the desire for a single end to end system

- from the first component parts being picked in stores, to running the reports for final handover and

- the ability to stay at the cutting edge of technology

that lead to Lighthouse choosing to develop it’s own bespoke system. This had

the added advantage that it opened up funding opportunities and support from

universities through knowledge transfer partnership programs and innovate bids. We successfully deployed

the system both in the factory and on site for module delivery and had

Lighthouse continued to operate, the system had a lot of promise, but it was a

lot of work and required more dedicate resource as other distractions slowed

development.

|

| Lighthouse MES |